Green hydrogen is seen as the fuel of the future. It seems so simple – just plug in your electrolyser to a solar panel, just as you plug in your iPhone to the charger, and get emission-free clean hydrogen. Blue hydrogen (produced from gas and capturing the carbon-dioxide) seems clearly not as clean – emissions throughout the entire process. I find it utterly fascinating – how and what can we do to reduce GHG emissions and decarbonize our economies? Unfortunately, the more I read, the more new and contradictory information I become aware of.

This op-ed focuses just on the issue of emissions related to hydrogen production, leaving many other issues to another day, foremost my favourite topic technology developments and break-throughs.

Do electrolyers and renewable energy go well together ?

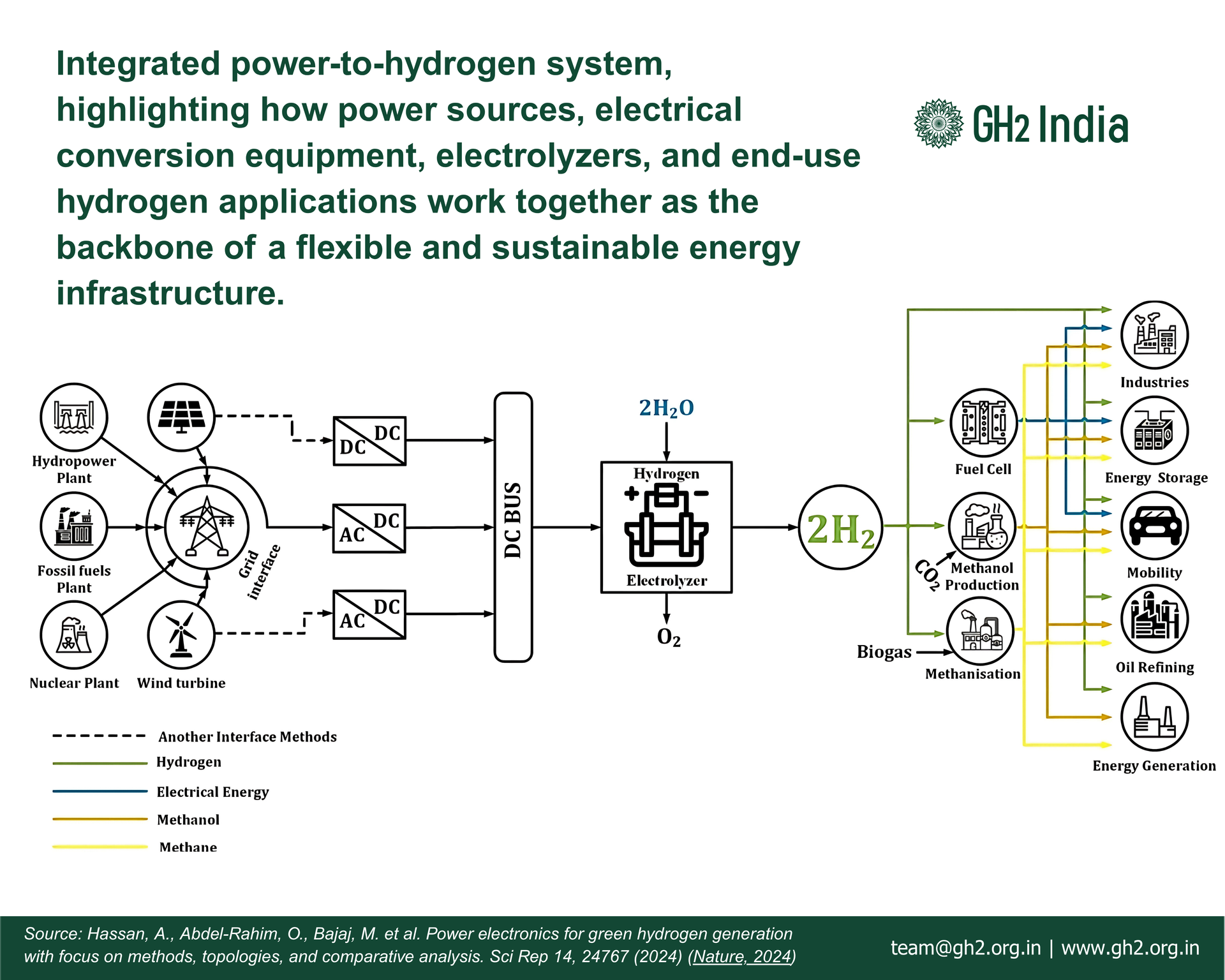

How do electrolysers, designed for stable current, perform when subjected to intermittent electricity flow, as is supplied by renewable energy? A study was recently published of 130 publications covering the impacts of intermittent operation on alkaline and PEM electrolyzers from the year 2000–2023. (“Impacts of intermittency on low-temperature electrolysis technologies: A comprehensive review Emma Nguyen, Pierre Olivier, Marie-Cecile Pera, Elodie Pahon, Robin Roche”). The review encompassed issues related to efficiency, gas quality and durability arising at all operational scales, from the cell to the system level. The key points from reviewed publications can be summarized as follows:

i) “performance and durability of electrolyzers at all levels of the system operation, are significantly influenced by the variation of temperature and electrical load conditions,

ii) both the performance and durability of electrolyzers are impacted by the frequency of intermittent cycles during intermittent operation,

iii) short current interruption or decrease promote partial performance recovery,

iv) the stiffness of ramp-up and ramp-down events typically encountered in intermittent operation has an impact on the efficiency, gas purity and degradation rate,

v) the frequency and waveform of ripple factors encountered in power conversion units impact the efficiency and degradation rate of electrolyzers.”

This is immensely technical. What it boils down to is electrolysers do not perform as well with constant fluctuations, and degrade quicker, meaning cost projections can potentially be too optimistic.

One of the less obvious, but just as relevant issues is gas purity. This is confirmed by a study on “Comparing prospective hydrogen pathways with conventional fuels and grid electricity in India through well-to-tank assessment” (Sachin Chugh*, Chinmay Chaudhari, Alok Sharma, G.S. Kapur, S.S.V. Ramakumar of Indian Oil Corporation Limited, Research and Development Centre) came up with an estimate of 2.1%-5.65% total H2 loss only in production due to venting, hydrogen crossover, and purging to remove impurities.

My sense electrolyser manufacturers know these issues, and are working tirelessly to improve the performance.

Who is the cleanest hydrogen of them all …. ?

If Snow White were to look into the mirror, and ask - ´who is the cleanest hydrogen of them all?´, the answer would probably differ according to where the mirror stands. Europe would clearly say green, the USA would possibly allow for low carbon (blue) hydrogen, South Korea and Japan have noticeably tried to avoid the debate. As India tries to position itself, there were some amazing developments and articles in the last 4 weeks that caught my attention. “

In its Climate Issue of June 24th , The Economist pointed out the solar-power paradox – “Solar panels are bought because they are cheap, and mostly from China. But polysilicon, the raw material for solar panels that quietly generate electricity for 20-30 years without emitting any carbon whatsoever, is often made using coal, the most emissions-intensive fuel of all. Hopefully, this is an interim phase only, and once the price is right, solar panels will generate the electricity to melt the sand using the endless flux of photons from the sky, creating material for new, cheaper solar panels, which will be used in ever more surprising ways”.

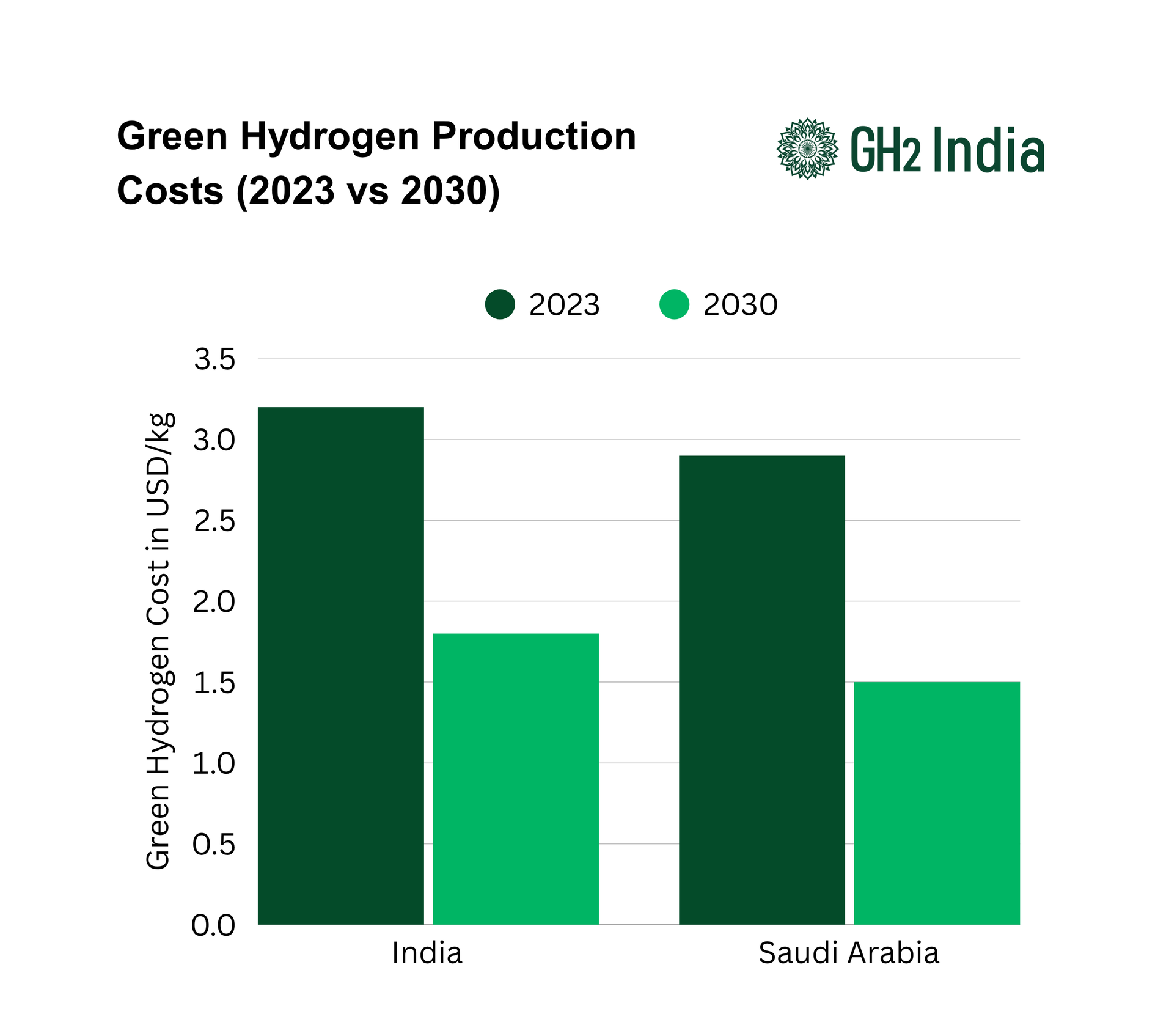

Another study was released in the Netherlands reviewing the GHG effects of green hydrogen (Worldwide greenhouse gas emissions of green hydrogen production and transport, Kiane de Kleijne, Mark A. J. Huijbregts, Florian Knobloch, Rosalie van Zelm, Jelle P. Hilbers, Heleen de Coninck & Steef V. Hanssen ) The study reviews the life-cycle greenhouse gas emissions for 1,025 planned green hydrogen facilities, covering different electrolyser technologies and renewable electricity sources in 72 countries. “We demonstrate that the current exclusion of life-cycle emissions of renewables, component manufacturing and hydrogen leakage in regulations gives a false impression that green hydrogen can easily meet emission thresholds. Evaluating different hydrogen production configurations, we find median production emissions in the most optimistic configuration of 2.9 kg CO2 equivalents (CO2e) kg H2−1 (0.8–4.6 kgCO2e kg H2−1, 95% confidence interval). Including 1,000 km transport via pipeline or liquid hydrogen shipping adds another 1.5 or 1.8 kgCO2e kg H2−1, respectively. We conclude that achieving low-emission green hydrogen at scale requires well-chosen production configurations with substantial emission reductions along the supply chain.”

Blue hydrogen gets promoted as low-carbon hydrogen, and as the solution in the short-term. But is it really “low-carbon”? A report from the UK organisation Carbontracker.org comes to quite a different conclusion (https://carbontracker.org/reports/kind-of-blue/ ). This report evaluates the impact of upstream emissions to determine whether or not gas-based CCUS technologies could have a positive climate impact, assuming the technology would work as claimed by the CCUS industry. The report reveals that CO2 emissions from Blue Hydrogen and Gas-CCS projects could be two to three times (200-300%) higher than reported when considering upstream emissions from gas extraction, processing and transport.

Due to their specific geographic location, Japan and South Korea have greatly promoted hydrogen and ammonia, and to a degree overlooking nuances in production type. But as Argus Media reported, South Korea in a recent auction on May 24th set parameters for eligible bidders that are likely to favour carbon capture-based low-carbon ammonia projects over those produced with renewable hydrogen via electrolysis. But most notably, the government has outlined that any CCS projects will need to capture 90pc of carbon emitted in order to qualify for the bidding market. The 90pc threshold will exclude several low-carbon ammonia production projects that operate on steam methane reforming (SMR). (Retrofitted CCS capabilities on SMR plants typically are unable to capture more than 50pc of carbon emitted, while newbuild CCS SMR plants may be capable of capture rates of around 70-95pc).

At least some good news about not forgetting low-carbon hydrogen is but one of the instruments towards decarbonization ! Hopefully, these articles / studies will remind policy makers to look into and include the scope 3 emissions in the standards.